The Covercat 900 Series Pipe Snake has been developed to fulfil the need for pipe coating, repair & inspection tool which is able to negotiate tight corners, in any direction, and able to climb and descend inclines

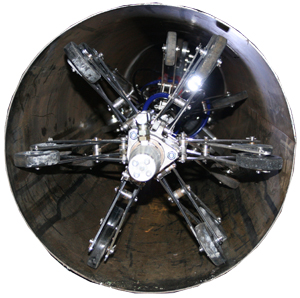

The Pipe Snake is driven through the pipe by three independent drive units coupled together. Each drive unit has independent suspension that allows it to automatically adjust to the size of the pipe. This mechanism uses a design which guarantees that the drive unit is always on centre line of the pipe.

The Pipe Snake’s head unit can accommodate many additional forms of attachments that can be mounted on the front of the snake, such as a repair tool to fill holes and mend pipe joints, a grinding tool for preparing a refined pipe surface for coating, to a video camera for internal inspection of long complex pipe forms. Future enhancements contemplated include a laser optic measurement system for more accurate measurement of pipe wall thicknesses.

The equipment can be set up to apply PU – rapid setting polymeric lining systems, or epoxy resins, as notified to CoverCat at the time of manufacture, for a wide range of mix ratios.

The systems are typically Trailer or Skid mounted and comprise; Positive displacement metering pump with component material reservoirs, Heating systems, Computer controlled monitoring system, Umbilical lining hoses, In-line mixer and Spray application head.

The units are manufactured to meet the demands of handling rapid cure and filled materials mixing and gelling within 60 seconds.